My Experience while building World's Largest Hydro rocket

World's largest Hydro-Rocket

How we made World’s

largest Hydro-rocket

Sir with due respect I am writing this note which will

highlight the practical challenges we have faced while making World’s Largest

Hydro-Rocket.

It all starts from scrap.

They willingly accept me and asked me to build a model to physically simulate every possible aspect of the rocket (which we had done till the last moment of the launch). Fortunately, I already had one (2 half litter bottles joined).

We have done its flight test just for fun and it

really flew to roughly an altitude of 25-30 meters.

This rocket answers our question:

Ø Can

we build?

Ø Do

we have required materials?

Then we did some research for required materials.

Majorly we were searching for bottles with our required specification (2

litters minimum with a smooth geometry and nozzle cone), adhesive which could

hold 80-85 psi of pressure and some other small tools.

Still, the test we have

done were not satisfactory and so we were in argent need for the material. But

there was a delay. We were already lacking behind as per launch date

(4-10-2019) so we collect bottles from scrap and adhesive from nearby market.

It was enough to do the required test.

Our next objective was to test the joint (single)

along with to experience the launch pad.

Still we have long way to go.

We used different adhesive now -Araldite. Because: The

setting time of the previous adhesive (fevitite) was too fast to work with

hence we were in need of such an adhesive which could give required strength as

well as enough time to work with. We keep setting time as 6 hours.

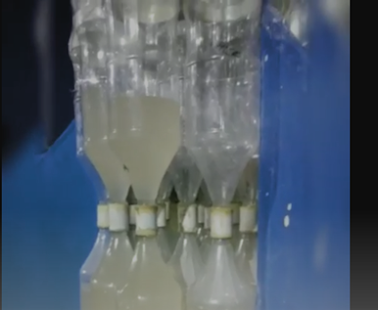

To join the module, we used 32mm diameter PVC pipe and

threads (generally used for plumbing). The PVC pipe inner diameter was just

enough to fit the mouth of the bottle externally and then we glued them with

araldite. After 6 hours of setting time

we tested (without water, static test) and fortunately it withstands 60 psi

without any leakage then we didn’t pressurize further due to safety reason. But

when we took the same for launch site it starts leaking just after 25 psi from

that very joint. But later we found that it was due to mishandling. So, by far

we had tested all kind of joints using which we were going to connect all

bottles up to 4.0 meters.

We had only 1 week left for the launch but yet we

didn’t have material to start to build the main rocket. Till we get the

material, we then start working for the launch pad (release mechanism).

We had many proposed ideas for release mechanism, we

discussed many models including those on internet. But most of them got

rejected either because we didn’t have required material or they were not

reliable for the present model. Later we finally agreed on locking mechanism.

It was easy to build and more reliable as it operates manually. Its 3-D

modelling help us to look into its manufacturing problems which we solve parts

by parts and then we had our final 3-D scale (1:1) model of our launch pad.

We had 5 more days for the launch.

By then our materials also arrived- 1000, 2 litter

plastic bottles, adhesive, cutting tools, PVC pipes etc. and materials for the

launch pad were collected from the workshop (not that of University).

We asked for volunteer and about 14 volunteers arrived

who worked throughout the project and it is because of their working force that

helped us to do everything within our time limit.

Now joining bottles has their own problem:

1) 1) It

was very irritating because we were working with araldite with our bare hands.

Once it got harden in hand it was too difficult to remove.

2) 2) The work has to be done with many concerns, like- in order to fit one bottle into another we were needed to enlarge the diameter of one bottle by just not more than 1mm. and the same has to be done to all 133 (required) pairs. Because we knew that there will be some defective item so 150 is what we have targeted. So, lots of work has to be done.

3) 3)

1) 4)After

putting araldite when they were left to get harden, because the araldite was

just a viscous fluid s it was flowing out of the region. So, they were

periodically turned upside down.

It took entirely one day and night for nearly 12

people to cut, expand, file, glue and fixed them. So, by next day we have

nearly 170 set of bottles.

It was really a good experience to do real engineering work.

It took us two day to measure, cut, positioned and weld all the parts.

All was going well, now we have to make pressurization

system which is the heart of this project. The design we had was totally based

on our previous test.

For pressurization too we had many ideas but most of

them were not feasible. Another important thing was that we were not familiar

with the problems relating to pressurizing water in a chamber with multiple

nozzle. From our long discussion we came into conclusion that we will use

rubber cork individually for each mouth as a water shield and drilling holes at

its center than pass pipes to pump water as well as air.

(Important thing to mention here is: the way we were

solving our problems. What we were doing was to create a fixed path and then to

solve the problems that comes in that path. This is good approach but only when

we are fully aware of every possible happening which in our case was not. We

were inexperienced in this domain. Although we made exactly how we had design

but because we were inexperienced, we couldn’t fully analysis every possible

problems we were about to face.)

Under high pressure the expansion of the pipe is so large that it totally and rigidly fits in mouth and hence will not release the bottle. Due to lack of time as well as knowledge of plumbing the joints of the base and other pipes (of the pressurization system) were not tested taken as granted. We were totally aware of the possible source of failure but because we were working at night and since the next day was the launch day. We had no choice.

After reaching to the launch site by 7 am we took some

rest and started to assemble at the launch pad. Then it’s the time when things start

getting seriously wrong. We couldn’t efficiently work because we hadn’t sleep

last night. And then the pipes were not getting inside the mouth. The main

problem is- We didn’t know why? Since for single stage we did it easily then

why not now. We initially thought that the pipes were too long as well as

uneven (by few cm) so some of them were getting stuck in the mouth. We cut the

pipe by 12 cm. No improvement!

Our problem was:

Those (blue) pipes, which were supposed to make the

nozzle water tight during air pressurization, were not going inside the mouth

of the bottles.

We were supposed to launch at 10 am but we have to postpone

to 2 pm. However, the guest was busy and because he had to leave so we

assembled anyhow and presented him – special thanks to Manik Sir (lab

assistant).

We couldn’t launch even by 2 pm and again faculties

postponed it to 5:30 pm.

We lost our hope by 11 am only but still we worked- we

pull out the long pipes and forcefully inserted the blue pipes, with kicks and

hammers, inside the mouth of the bottles. Then by 6:30 we start filling water

and pressurizing the rocket. We were surprised to see for a while it worked

well but as pressure increases many faults comes in picture. It is here where I

have seen more faults then functioning in my entire life.

Faults:

- Bottle

leakage more than 6 out of 19

- Leakage

at the base (at T and pipe joints)

- Leakage

at the blue pipe

- Back

flow of water

- Inefficient

pressurization

- Uneven

water level

- Lack

of water pump and low volume air compressor.

- Launch

pad not level with the ground

- Wrong

orientation of the rocket in the launch pad (which is the major carelessness

due to which rocket couldn’t liftoff)

- Positioning

error of the supporting rods

Etc…

At the end the rocket

couldn’t lift off the ground but instead due to its own weight it crushed the

pressurization system and, in this way, we had no choice but to accept our

failure.

After the failure.

The result was as we have

concluded early that morning. But by nature(human) we were sad because we have

tried all the way we could. I could have taken that as a positive vibe but it

was I (the leader) who was more broken then rest of the members.

Most of them left for

home. I and the teammates along with Sir Manik (lab assistant), Sir

Ponmaakishan and two more faculties were there to help us to collect the items.

We didn’t have enough energy to collect all the items and bring back to the

hanger (about a Km). So, the important items were collected and the rest were

left for the next day.

What next?!!

By the time we reach the hanger, most of the team members had left for their room and only few of us were there. Basit, Shiv and Ankit were waiting for me.

That night I compensate

my last 7 days of restless hours. Next morning was a normal day for me. We

received message from Sir informing that they have accepted their reattempt

application. I called Basit, he first asked me what I have decided then after

hearing my answer he replied with- “May soo raha hu, mayrayko soonay day”. I

went to see the exhibition for the first time but I was late. I forgot to

mention that the whole project was a part of a week-long space exhibition as

organized by the Aerospace department of Chandigarh University. Then when I came

back, I found few of my team mates including my friends too waiting for me.

They told me that if the team will do the project then it’s only under my

leadership or else it’s just the end for all. They were not willing to do

without me not because I knew more (many possessed more knowledge than me) but

rather because (as few said) they may loss the ‘followed path’ and also my

energy motivates them to work whole night. And because they were not willing to accept

then I too told them- “Ok, leave the project” and then left for the room.

An hour later I came down

to go for the stationary shop to buy a cold drinks but I found them still there

talking to each other and waiting for me. All of them. They looked at me and

again started to give me a motivational lecture (I forgot). This time they

really convinced me. I simply wake up and without a word left for the room

(they were unaware of my decision). I changed my dress and then came down and

told them (I still remember that word as that was the time when I have decided

to get success anyhow): “Chalo, bahut kaam baki hay”.

We were having five more

day to rebuild the rocket and I wasted the first half day. By evening we went

to the hanger and discussed the plan.

First, we must be sure

that we have learned a lesson which we really did. Then we must go through our

mistakes, re-evaluate our design and discuss to improve and then implement them

physically. That’s lot to do. But now it was a bit easier because the most

advantage point for us was our ‘experience’ of what could go wrong.

We have enough bottles to

build one more entire rocket but it was not necessary as most of the stages

were OK. We only needed few- 7. Because we were enough but running out of time

so I divide all into three teams.

Rocket was the most critical part of the

entire system. We can’t improve the design but yes, they definitely have to

look after and improve the process. They decided to go slow to improve the

result. Most of the faults were in joints due to air bubbles in between and

uneven breadth of the araldite. They have to check them and remove during the

process and also to avoid flow of the Araldite the mixture ratio should be

proper. Although we didn’t alter the ratio (50/50) but what we did was to keep

it for a while so that it naturally gets hard a little bit and so easy to use.

Our decision was not bad. It really helped us to improve our quality of the

joints. Most of the team mates were engaged in this work.

Ankit, me, Basit and two

juniors: we took the charge of leftover things.

We mainly indulged to reevaluate the

entire design and do all shorts of possible but reliable changes. It includes

most of the things like launch pad, pressurization system etc. Launch pad was

mostly under Basit and Ankit’s vision and pressurization system was what I got

in my list. But we three constantly comments on each other works.

For launch pad, we didn’t

change anything in design but only its measurement. Previously, those four rode

in which the entire rocket was placed got crashed at the end due to its own

weight and later we found that it was the miss alignment of one rode due to

which the base plate of the rocket gets tightly fixed and so the rocket

couldn’t free itself but get crashed. So, that four rods need to be positioned

exactly at the same defined position where the hole of the base plate comes in

and also should be vertical so that all loads(weight) get distributed equally

as we wanted.

All the above system were

ok. Initially they got failed due to our carelessness and error in measurements.

The main cause of failure was the pressurization system. Till then we couldn’t figure

it out what really went wrong there. Initially we though that it was mostly

because of its weak strength to handle shear load at various joints which

results in leakage. So, we didn’t make any change in design but only improve

our strength.

It was this time we found

why we couldn’t insert the pipes into the bottles. Because we didn’t have

enough force (manual power) to insert them. This sometime happens when we were

testing our single nozzle rocket. But we merely took it into consideration. So,

for multi-nozzle the ‘error’ grow exponentially and became a big problem. We

thought to replace those long pipes with just the base pipes (blue one) only and

then we will pre-insert into the bottle and into the pressurization system. For

water leakage we tied the blue pipes with hose clamp. It really makes our work

easy. It definitely improved but no success.

We then concluded that

the pipes (those to go into the nozzle) diameter we too tight and so when we

make our new version (with metal pipes) we won’t face the same because they

were exact and with one layer of taping it will become water shield too.

But the launch date was near, we have two more

day to launch. By that night, around 12:00 am we assembled the new

pressurization system. Initially, we had rectangular configuration but this

time we made in a zig-zag configuration because we were facing problems to join

various metal pipes at the T and L-joints. We assembled and by 1:00am we were

ready for static test. This time we succeeded. Wait, hold on! We succeeded only

to insert those pipes into all 19 nozzles with a little hammering. But it was

ok for us.

Next,

at that very night all were very excited to see how water gets fill and air

pressurization. So, despite being tired we were ready to simulate how long it

might take water to fill the required height (two vertical stages About 1 m).

That late night it was

difficult to find that amount of water (152 litters) and also water pump. But luckily,

we had a tape nearby. It also had enough pressure to fill the water. Then we

started to fill the bottles. There were two valves, one for air and the other

for water. As soon as we stared to fill, we face some leakage problems. But we

fixed them and continue. This is the time when we show uneven raise in water

level in all columns of bottles. Initially, we thought it won’t be much to

consider because the water level was not much different. But as time goes on,

the difference in water level was getting higher and higher. Now why this

happens?

Now just think how you

feel.

‘You stood after failure, you figured it

out as much defects/problems you had and solve them step by step. After doing

all possible modification with no time left for extra, result is same.’

It was already 2:30 am

and now we only have next day to solve that freaking problem. We had no choice

then to pack-up and go to sleep if we want our next day to be productive.

Next day, shiv team were

busy testing leakage and they found only one. That’s a good work. Out of 9, 8

vertical stages were Ok. But we needed only 6. So, we have 2 extra. Then we

assembled and discussed about last night problem. Different members have

different solution but none of them were feasible. Either they were what we had

rejected early or practically can’t implement at that time. Some were not in

discussion as they believe now nothing could happen and blame that we have

stuck to same idea rather than changing it. Yes, I accept but what could I do.

Even HOD was with us pointing out what we have already observed. I then

remember one. Initially when we were discussing about pressurization system.

Sir had an idea of filling all stages individually but we rejected because it

was too risky to proceed. If any accident happens and the rocket get launched

out of our planned time then it could dangerously harm the one at the top. Also

for as high as 5-meter rocket, manually filling was not an easy task. Everyone

was busy in debate. I thought let me try. I call Basit and then we two make the

required setting for a ‘Dice test’.

First, with a single nozzle

bottle (one bottle) the entire mechanism was setup. It worked!

So, did in all previous

test. Nothing new! Next, we thought to increase the number of nozzle to 3. We

made the required setting for 3 nozzle configurations. Hurry! It worked again.

I don’t know about other but I was so relaxed that I couldn’t think any more

problems. That’s a success.

Now, everybody was sure

that the rocket will get launched.

What modification were to

be done for new configuration?

Not much, launch pad was

same and so all but only the modifications were at the mouth of the bottles. We

were to made 19 valve for each nozzle which were to be fitted at the top of the

bottles and 19 corks (which we already had) to be fitted at the bottom of the

nozzle to get the stage water tight. It might sound easy but No! Now we have to

do most of the work, till the rocket get launched, manually. Any wrong method,

failure is sure. By night we did all what were left, like making nose cone

(credit goes to Ajay, Milind and Anjali), fines (credit goes to Ankit) etc. and

also did one more test with all 19 nozzles. Success!!

Finger-crossed.

Next, morning we all get assemble at 6:00am and then took all the required tools and materials at the launch site. Now, everything went as per plan. Some small problems arose but we handle. Winter was near so we enjoyed the heat of the sun but soon got irritated. Slowly and steadily, team member starts assembling the rocket. Because nose cone was not ready yet. Few were given that task. Other were busy levelling, adjusting, fitting and fixing the rocket in the launch pad.

Diameter comes out to be 52 cm and height 5.2meter in size we broke the record. Now, next was how far it will reach. We then began to compress the columns. Some minute things were to be consider here like the way we compress the bottles. They shouldn’t be done randomly otherwise due to nonuniform pressure distribution about axis, the rocket might get tilt and could possibly fail the launch.

I slowly compressed the air one by one. First, all 19 were pressurized up to 30 psi then our next aim was to pressurized them to 70 psi (which we planned). 13 were successfully pressurized with one leaking but we fixed it at that very moment. As we started to pressurize the 14th one, one of the bottles get blew-off. All were surprised and shocked. One stage starts leaking out from the base as its cork got lose since the rocket gets tilt to its side because of the force from the blast. But, Basit and Ankit handled the situation in the ground and then Shiv decided to get launched without delay. Now our goal was not to break the record but rather to get launched out of the launch pad. I stop pressurizing the system. Nose cone was handed to me where electronics were fitted. I placed it at the top and then I was pulled out of the zone.

Ankit and Bhanu were given to pull the clamp and Basit starts countdown: 3-2-1 and there it gets lift off the ground, our 10 days of relentless work, day and night, vertically towards the night sky glittering with stars and moon. Finally, it gets launched. I was still sitting at the top of the crane shocked and void of thought looking at the team mates joyful moments. I was happy because we did it together. There were other 100’s of audience too and they too were happy because it was not only our success story but success for whole Aerospace department of Chandigarh University.

Then we collect the data.

As per that we achieve 104 feet (previous record was 73 feet). So, by this way

our team of 17 young and unexperienced students 3 faculties with Sir Manik made

a new world record of World’s Largest Hydro-Rocket achieving World Record

height of 104 feet.

Comments

Post a Comment